Overview of Automotive Hot Runner: Specifications, Types, Applications, and How It Works

Automotive hot runner systems use heat‐treated H11, H13 or 420 stainless steel (≥35 HRC) and operate at pressures up to 2,500 bar, with plate thickness from 40–100 mm and plate sizes from 50–450 mm, typically powered by 230 V AC and heated by pressed-in external heaters for uniform temperature. In addition to this, they have three major forms: the open manifold is one, which has simple, permanently opening nozzles, and easy assembly; there is the sequential valve-gate, which enables the use of programmed gates, which provide accurate flow and consistent parts; and the hot-half manifold which is a pre-assembled block, whose cost is higher though making the job quicker during set up. Moreover, they are applied to dashboards, bumpers, interior trims and the sections under bonnet since they provide smoother finishes, constant measurements and highly resistant to hot and stress conditions. Lastly, the hot runner keeps the polymer melt at optimal viscosity and injects it directly into the cavities through nozzles and sensors, due to which the fills occur quickly, and waste and cooling is minimal, hence all components come at the very strict automotive standards.

What is an Automotive Hot Runner?

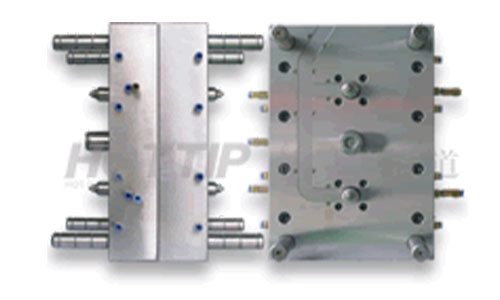

First are Automotive Hot Runner systems - an injection moulding advanced technology, which maintains the plastic in molten state in heated channels and injects the plastic to mould cavities without the traditional sprues and runners. Further, the technique secures uniform quality of parts and dimensional accuracy that is crucial to the interior trims. It also removes cold runners, which minimizes the level of wasting plastics, and lowers the cost of using material. As a result, there is a reduction in cycle times, which increases throughput and makes a business more profitable. In addition, the system is electrically safe IS 16504/IEC 60204-1, quality management (ISO 9001:2015), has testing and calibration (NABL/ISO IEC 17025) and export control (CE, UL and CSA).

Specifications of Automotive Hot Runner

| Specification |

Details |

| Material |

H11, H13, 420 stainless steel; heat‑treated to ≥35 HRC |

| Operating Pressure |

Up to 2,500 bar for high‑pressure molding |

| Dimensions |

Thickness: 40–100 mm; Length & Width: 50–450 mm |

| Voltage |

Typically 230 V AC |

| Heating Method |

External pressed‑in heaters for even temperature distribution |

Types of Automotive Hot Runner

- Open manifold: With an open manifold, the tips of the nozzles are continuously open such that molten plastic can flow into the cavities. It also eases maintenance procedures lacking valve gates making the system less complex.

- Sequential Valve gate: It has programmable gates chronologically opened in a spaced out fashion that provides a fine control of the flow. As a result, cycle times decrease and part consistency improves - ideal for multi‑cavity molds.

- Hot Half Manifold: Mounted on the stationary mold half, it integrates manifold and nozzles into one preassembled block. Although it has a higher upfront cost, it cuts setup time and downtime.

Applications of Automotive Hot Runner

As the Top Automotive Hot Runner Manufacturers in Pune along with Automotive Hot Runner Suppliers and Dealers in Pune. Check our automotive hot runner uses:

- Dashboard Components: Achieves smooth surface finishes and tight tolerances for instrument panels.

- Bumpers & Body Panels: Handles high‑performance polymers while ensuring dimensional stability.

- Interior Trims: Delivers consistent wall thickness, improving aesthetic and functional quality.

- Under‑the‑Hood Parts: Withstands demanding thermal and mechanical stresses in engine bay components.

How Automotive Hot Runner Works

An Automotive Hot Runner system heats manifold channels to maintain polymer melt at optimal viscosity. Upon injection, molten plastic flows directly from the manifold through nozzles into cavities, controlled by heaters and temperature sensors. The result is rapid filling, minimal waste, and uniform cooling - ensuring every part meets strict automotive standards.

Automotive Hot Runner Ordering, Compliance, and Safety Information

For orders, compliance details, and safety guidance, please contact:

- Address: 406, Swaraj Capital, Moshi, Pune 412105

- Phone: +91 90280 18877

- Email: sales@hottipindia.com

We adhere to all relevant IS/IEC norms and voluntary BIS certification, ensuring energy‑efficient designs with complete documentation.

Why Choose Us?

- International Expertise: With branches across India, Malaysia, Thailand, Canada and China we are able to bring local service but global connectivity.

- Integrated R&D: End to end innovation: Our 3 dedicated divisions (Hot Runner Systems, AMPORT Connectors, Smart Temperature Controllers)

- Guaranteed Quality: NABL calibrated testing, strict procedures on QC, and ISO 9001:2015 ensure the invariable output.

- Customer‑Centric Service: We dispatch technicians for on‑site support and feedback, offering a one‑year guarantee on all systems.

Because of these strengths, Hottip India stands out among Automotive Hot Runner Manufacturers in Pune and Suppliers/Dealers in Pune.

Get Automotive Hot Runner in India | Hottip India

Hottip India is your trusted manufacturer, supplier, and dealer of Automotive Hot Runner systems from Pune. With ISO quality certification and a professional team, we deliver complete solutions—from consultation and prototyping to installation and after‑sales support.

Ready to transform your injection molding process? Contact us today to discuss your requirements and get a personalized quote.