Hottip India, a leader in Pharma Hot Runner Manufacturers in Pune and Pharma Hot Runner Suppliers in Pune, has over 25 years of hands-on experience in hot runner or hot manifold system design. Moreover, we specialize in Pharma Hot Runner Dealers in Pune to serve your precise molding needs. Our solutions - often sought under Hot Runner Systems and Hot Runner Injection Mold searches - combine innovation and reliability from concept through commissioning.

Pharma Hot Runner Suppliers and Dealers in Pune

Hottip India have expertise in Pharma Hot Runner systems as Manufacturers, Suppliers, and Dealers. Our manufacturing hub in Pune benefits from two decades of refining hot runner technology. Additionally, our sales and distribution network spans India and beyond. Today, more than 200 team members - including R&D engineers, quality control specialists, and after-sales experts - support over 200 clients in the pharmaceutical sector. Request a Quote to discover how our proven track record can boost your ROI.

Overview of the Pharma Hot Runner: Specifications, Types, Applications, and How It Works

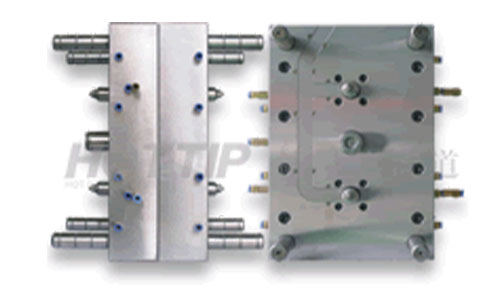

The Pharma Hot Runner Systems, typically made from stainless steel and operating at 220 V, is designed for pharma applications with an 8-cavity configuration and a 215 mm nozzle length. It comes in three main types: Open-Gate, which simplifies maintenance with fewer moving parts; Valve-Gate, offering accurate drool control for precision parts; and Valve-Less, combining simplicity with shot consistency. These solutions are commonly found in the application of tablet housings, syringe and vial molds, droppers, pipettes and complicated housings of medical devices. In addition, it escapes wastage, quickening of the cycle and qualitative and reproducible outcome because the hot runner applies equally and hot manifolds and thermocouples so it keeps the melt constant

What Is a Pharma Hot Runner?

A Pharma Hot Runner (another term is hot manifold system) is an environmentally-controlled injection molding tool, which injects molten pharmaceutical-grade polymers directly to each cavity, without solidification in the runner system. It is certified to stringent requirements like electrical safety requirements (IS 16504) and quality management (ISO 9001:2015) and is accredited to NABL-recognized calibration procedures. Export-compliant with CE, UL, and CSA marks, our systems ensure safe, consistent, and clean molding for critical pharma applications.

Specification of the Pharma Hot Runner

| Specification |

Detail |

| Material |

Stainless Steel |

| Runner Type |

Hot Runner |

| Usage/Application |

Pharma |

| Voltage |

220 V |

| Nozzle Length |

215 mm |

| Cavity Type |

8 Cavity |

Types of Pharma Hot Runner

- Open-Gate Hot Runner: The melt flows through an open nozzle directly into the mold cavity. This design minimizes mechanical parts, simplifying maintenance and reducing operating costs.

- Valve-Gate Hot Runner: Featuring a needle valve to open and close flow, this system offers precise drool control and clean gate vestige - ideal for high-precision pharmaceutical parts.

- Valve-Less Hot Runner: Utilizing thermal gates, it offers a balance between open-gate simplicity and valve-gate precision, with lower maintenance and consistent shot quality.

Applications of the Pharma Hot Runner

- Tablet and Capsule Housings: Produces uniform, defect-free housings for oral dosage forms, ensuring tight tolerances for automatic filling machines.

- Syringe and Vial Molds: Delivers high-clarity parts with smooth internal surfaces, critical for sterile pharmaceutical packaging.

- Dropper and Pipette Components: Ensures consistent wall thickness and gate vestige for leak-free fluid delivery devices.

- Medical Device Housings: Supports complex multi-cavity molds for inhalers or injectors with minimal cycle time variation.

How Pharma Hot Runner Works

The Pharma Hot Runner system heats polymer resin in a manifold and maintains melt temperature uniformly through precise thermocouples and controllers. Molten material flows through the hot channels, directly feeding each cavity without freezing in the runner. This process reduces waste, accelerates cycle times, and guarantees consistent shot-to-shot quality.

Ordering, Compliance, and Safety Information

As we are the leading Pharma Hot Runner Manufacturers in Pune as well as Pharma Hot Runner Suppliers and Dealers in Pune. For ordering, please refer to our standard lead times and customization options. All Pharma Hot Runner systems comply with IS/IEC electrical norms and undergo NABL-certified testing. Safety protocols include emergency shut-off features and over-temperature protection.

- Address: 406, Swaraj Capital, Moshi, Pune 412105

- Phone: +91 9028018877

- Email: sales@hottipindia.com

Why Choose Us?

- Expert Divisions: Hot Runner System and Industry Connectors (AMPORT) Divisions as well as Smart Temperature Controllers Divisions provide expertise.

- World Wide Presence, Local Back up: Branches in Malaysia, Thailand, Canada, China and India offer timely service and supply of spares.

- Quality Assurance: Our quality is certified by ISO 9001:2015 certification, NABL accredited measurement, and CE/UL/CSA export certification that testifies to our quality.

- Innovation-Driven Research And Development: We have 24 research and development engineers working constantly to perfect thermal management technologies and flow control.

- Customer-Oriented Service: More than 200 competent after-sales personnel ensure speedy after-sales service in installation as well as training aspects and maintenance.

Due to these strengths we emerge as Pharma Hot Runner Manufacturers in Pune, Pharma Hot Runner Suppliers in Pune and Pharma Hot Runner Dealers in Pune.

Get Pharma Hot Runner in India | Hottip India

Hottip India is a trusted manufacturer, supplier, and dealer of Pharma Hot Runner systems in Pune. Our Pune facility combines local expertise with global standards to deliver turnkey solutions.

Ready to elevate your pharmaceutical molding? Contact Sales today and secure tailored hot runner technology that drives efficiency and precision.