Hottip India, a leading Electronic Goods Hot Runner Manufacturers in Pune and Electronic Goods Hot Runner Suppliers and Dealers in Pune, brings 25+ years of expertise to plastic injection molding for electronic devices. Also known as Hot Runner Systems, our solutions - frequently searched as Hot Manifold and Hot Sprue System - combine cutting edge design with proven reliability. Over two decades of innovation under our belt make us a trusted partner for high precision molding.

Electronic Goods Hot Runner Suppliers and Dealers in Pune

We have expertise in Electronic Goods Hot Runner as Manufacturers, Suppliers, and Dealers with deep roots in industrial B2B. Our systems power molds for smartphones, laptops, and other gadgets across India and beyond. Based in Pune, we’ve served a growing base of clients for 25 years. Backed by a 200 member team - 24 in R&D, 28 in after sales, 16 in quality control, and dedicated production and sales staff - we deliver swift support and consistent product quality.

Overview of the Electronic Goods Hot Runner: Specifications, Types, Applications, and How It Works

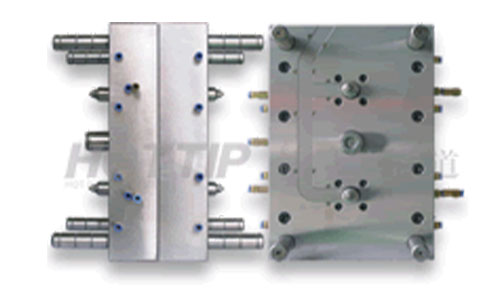

Electronic Goods Hot Runners are specialised systems designed to mould components with high precision and minimal waste. These systems operate at controlled temperatures between 255–260 °C to ensure a stable molten plastic flow. They consist of sprue bushes, manifolds, hot nozzles, and valve inserts, with nozzle diameters ranging from 4 mm to 12 mm. Moreover, the design accounts for thermal expansion, preventing leaks, and supports materials like ABS and similar thermoplastics. For ease of upkeep, parts like nozzles, heaters, and thermocouples are replaceable. There are three main types - Open (Hot Tip) systems for small parts like phone buttons, Internally Heated systems for uniform heat in plastics like polycarbonate, and Valve Gate systems that provide precise control for larger or intricate parts. These runners are widely used in moulding electronic device components, appliance parts, medical equipment, and packaging. During its operation, molten plastic is filled in through the injection unit into a heated manifold, and into the mould through insulated nozzles. Uniform viscosity is maintained at temperature zones and this creates consistency in quality and fine surface finish

What Is an Electronic Goods Hot Runner?

An Electronic Goods Hot Runner is a specialised system used in plastic injection moulding to keep the polymer molten as it flows into mould cavities, especially for electronic-grade parts. Moreover, it is designed and tested as per IEC/IS standards, ensuring all materials and wiring meet the IS 16504 (IEC 60204-1) electrical safety norms. Moreover, the contents are calibrated by ISO/IEC 17025-calibrated lab accredited to NABL. It is also CE, UL, and CSA certified thus completely compliant to be exported and used in other parts of the world.

Specifications of Electronic Goods Hot Runner

| Specification |

Details |

| Temperature Control |

Precise control at 255–260℃ for stable molten flow |

| Components |

Sprue bush, manifold, hot nozzles, valve inserts |

| Nozzle Sizes |

4 mm–12 mm sprue diameter |

| Thermal Expansion Design |

Accommodates component expansion without leakage |

| Material Compatibility |

ABS and similar thermoplastics |

| Maintenance |

Replaceable nozzles, heaters, and thermocouples |

Types of Electronic Goods Hot Runner

One of the leading Electronic Goods Hot Runner Manufacturers in Pune as well as Electronic Goods Hot Runner Suppliers and Dealers in Pune. We Provide following types:

- Open (Hot Tip) Systems: These inject molten plastic directly at the nozzle tip. Ideal for small to medium parts—such as phone buttons. They maintain temperature externally and are easy to service.

- Internally Heated Systems: Heating elements run inside the manifold channels, ensuring uniform temperature. This consistency is critical for temperature‑sensitive plastics like polycarbonate.

- Valve Gate Systems: Featuring a valve mechanism at each nozzle, they offer precise flow control and clean gate marks. Best for larger or complex parts, such as device housings and connectors.

Applications of Electronic Goods Hot Runner

- Electronic Device Components: Precision molding of smartphone frames, laptop bezels, and connector housings.

- Household Appliances: Parts for hair dryer handles, appliance buttons, and control knobs.

- Packaging: Thin‑walled items like caps, closures, and trays for consumer electronics packaging.

- Medical Devices: High‑precision components for diagnostic equipment and wearable health monitors.

How Electronic Goods Hot Runner Works

The system circulates molten plastic from the injection unit into a heated manifold. The melt then passes through insulated hot nozzles, into both the molds. Uniform viscosity is maintained by temperature controllers which control heat zones. As a result, parts solidify with minimal waste, consistent dimensions, and superior surface finish.

Electronic Goods Hot Runner Ordering, Compliance, and Safety Information

When ordering, specify:

- Model type (Open, Internal, Valve Gate)

- Nozzle count and sizes

- Material compatibility

All our systems comply with ISO 9001:2015 quality management and undergo NABL‑accredited testing. For safety, we adhere to IS 16504 (IEC 60204‑1) wiring standards.

- Address: 406, Swaraj Capital, Moshi, Pune 412105

- Phone: +91 90280 18877

- Email: sales@hottipindia.com

Why Choose Us?

- 32k+ Projects Delivered: Proven track record across industries.

- Punctual Delivery: On‑time shipments aligned with your production schedule.

- Smart Technology: Integrated temperature control for peak efficiency.

- Professional Team: 200+ specialists in R&D, QC, and after‑sales support.

- Cost‑Effective Solutions: Competitive pricing without compromising quality.

Because of these strengths, Hottip India remains the preferred Electronic Goods Hot Runner Manufacturers in Pune and Electronic Goods Hot Runner Suppliers in Pune.

Get Electronic Goods Hot Runner in India | Hottip India

Hottip India is your trusted manufacturer, supplier, and dealer of Electronic Goods Hot Runner Systems in Pune and throughout India. Leveraging global support networks in Malaysia, Thailand, Canada, and China, we ensure timely delivery and local expertise.

Ready to elevate your molding process? Request a Quote or Download Our Spec Sheet today by contacting us at sales@hottipindia.com or +91 90280 18877.