Hottip India is a leading Hot Runner Manifold Manufacturer in Pune, as well as Hot Runner Manifold Supplier in Pune and Hot Runner Manifold Dealer in Pune. With over 25 years of hands on experience since our founding in 2000, we’ve perfected runnerless molding systems - also known as hot manifold systems or runnerless molding solutions. Our expertise in Hot Runner Systems and consistent performance engineering has earned us a reputation for durable, energy efficient manifolds.

Hot Runner Manifold Suppliers and Dealers in Pune

We have expertise in hot runner manifold solutions as manufacturers, suppliers, and dealers. Our Hot Runner Manifolds are used extensively in automotive, packaging, and electronics industries across Pune and beyond. Moreover, our integrated global support network - spanning Malaysia, Thailand, Canada, China, and India - ensures responsive service for over 200 satisfied clients. In Pune alone, our 200 member team (including 24 R&D engineers and 16 quality control experts) guarantees seamless delivery from design through commissioning.

Overview of the Hot Runner Manifold: Specifications, Types, Applications, and How It Works

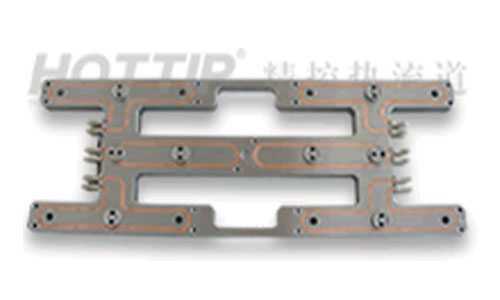

The hot runner manifold is made of H11, H13 and 420 stainless steel, heat-treated to over 35 HRC, and works up to 2,500 bar with a thickness of 40–100 mm and length/width of 50-450 mm; it runs on 230 V AC and uses external pressed-in heaters for even temperature, while NABL-accredited testing ensures the thermocouple and insulation are verified. Moreover, there are three main types: the open manifold, which allows continuous melt flow for simple maintenance and lower cost; the sequential valve gate, which uses programmable gates to cut cycle times and boost consistency in multi-cavity moulds; and the hot-half manifold, which sits in the mould’s stationary half for faster changeovers despite higher investment. These manifolds are also used in automotive trims, and consumer electronics casings and incontainers because they have great surface finish, tight tolerances and short cycle times. Therefore, maintaining the correct melt temperature all the way to the cavity, they shorten the cycle times, minimise wastage and assure quality of parts.

What Is a Hot Runner Manifold?

A Hot Runner Manifold is a precision-engineered component that delivers molten plastic directly into mold cavities via heated channels. It replaces traditional cold runners, reducing material waste and cycle time. Our manifolds are of high ISO 9001:2015 quality and are in compliance with IS 16504 (IEC 60204-1) electrical safety. Additionally, NABL‑accredited testing ensures temperature-control accuracy for consistent part quality.

Specifications of the Hot Runner Manifold

| Specification |

Details |

| Material |

H11, H13 & 420 stainless steel; heat‑treated to ≥ 35 HRC |

| Operating Pressure |

Up to 2,500 bar |

| Dimensions |

Thickness: 40–100 mm; Length/Width: 50–450 mm |

| Operating Voltage |

230 V AC (standard) |

| Heating Method |

External pressed‑in heaters for uniform temperature distribution |

| Testing & Calibration |

NABL (ISO/IEC 17025) for thermocouple & insulation verification |

Types of Hot Runner Manifold

- Open Manifold: Open manifold does not have a mechanical shut off and permits direct flow of the melt into the cavities. Consequently, it is easier to maintain, cheaper to purchase out of the box and provides even melt distribution.

- Sequential Valve Gate: It has programmable gates that open and close in sequence resulting in reduced cycle times and improvement in part to part consistency. It is very suitable in complex multi cavity molds where there is want of precise control.

- Hot Half Manifold: Preassembled runners eliminate changeovers and maintenance concerns in that hot half manifolds incorporate the runner system into the same mold that remains stable in use after the runner system is fully installed. The initial cost is higher but downtimes and possibilities of error are minimized significantly.

Applications of the Hot Runner Manifold

- Automotive Components: Molding interior trims, exterior panels, and electronic housings with minimal flash and superior surface finish.

- Consumer Electronics Housings: Producing lightweight, high‑precision casings for mobiles, laptops, and TVs, benefiting from rapid cycle times.

- Packaging Industry: Manufacturing durable, thin‑wall containers and caps with tight dimensional tolerances, reducing material usage and scrap.

How Hot Runner Manifold Works

A Hot Runner Manifold works by maintaining the plastic melt at a precise temperature from the nozzle tip to the mold cavities. Heaters embedded around the manifold channels prevent premature solidification. Consequently, cycle times are shortened, material waste is minimized, and part quality is consistently high.

Hot Runner Manifold Ordering, Compliance, and Safety Information

When placing an order, Hottip India’s ISO‑certified ERP system ensures traceable workflows and on‑time delivery. All manifolds comply with IS 16504 electrical safety, ASTM‑equivalent material norms, and carry CE, UL, and CSA export certifications.

- Address: 406, Swaraj Capital, Moshi, Pune 412105

- Phone: +91‑9028018877

- Email: sales@hottipindia.com

Why Choose Us?

- Industry Expertise: More than twenty-year innovation experience supported by an R&D dedicated team.

- Worldwide: Service, and a ready supply of spare parts are available around the globe through local branch offices throughout Asia and North America.

- Quality Assurance: ISO 9001:2015 certification, and NABL-accredited testing ensure that the quality of its performance can be maintained.

- Customer Centric Service: Visits by technical personal on site, individual consulting and one year’s product warranty.

Due to these advantages, Hottip India is among the best Hot Runner Manifold Manufacturers in Pune and Hot Runner Manifold Suppliers in Pune, with the unparalleled quality of reliability and price.

Get Hot Runner Manifold in India | Hottip India

Hottip India is your trusted manufacturer, supplier, and dealer of Hot Runner Manifolds in Pune. With a team of 200 professionals and a global network, we deliver turnkey hot runner solutions engineered for excellence.

Ready to elevate your injection molding process? Get Your Quote today - call us at +91‑9028018877 or email sales@hottipindia.com - and experience the Hottip difference.